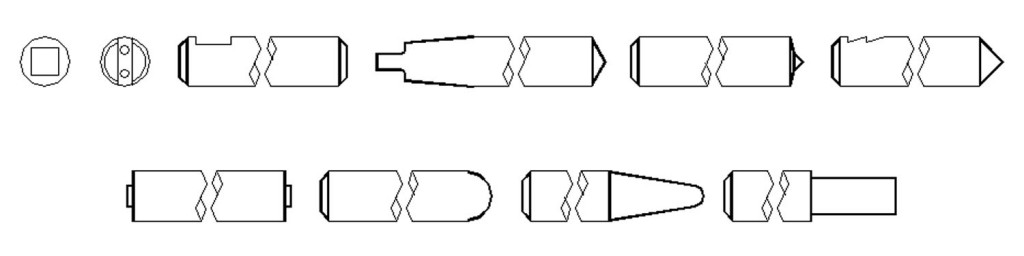

Form Grinder Sample Configurations

FORM GRINDER (FPG)

SAMPLE CONFIGURATIONS

FPG – MACHINE SPECIFICATIONS

FPG – FORM GRINDER

ITM Tool Grinding Machines are Designed for 24 Hour Production…

7 Days a Week.

ITM’s Form Grinder (FPG) is designed to form both ends of a part complete in one setup. Two rigid chucks are mounted opposite each other onto high precision rails. Clamping with two individual Chucks for grinding of both part ends in one set-up or clamping with Chuck & Center.

The machine has a heavy, welded, stress‑relieved base. The twin Workheads (A axis: Tool rotation), Wheel head index (U axis: wheel angle), cross slide (Z axis: wheel infeed), longitudinal slide (Y axis), and one workhead (X axis: workhead longitudinal travel) are CNC controlled.

The Wheel head angle can be fixed or as an option equipped with ITM’s pivot Axis with high precision belt technology eliminating any possibility of backlash. It is mounted onto the Y-Z cross slide table and it is capable of rotating from 0° to 90°. The wheel head can also rotate into position to dress the wheel with the standard dresser. Each desired wheel shape is generated by interpolating the machine’s Y and Z-axes, which maneuver the wheel along the dresser. The unique design of the machine allows for dressing while loading, therefore the dressing does not increase the total cycle time of a tool.

For more information regarding ITM Form Grinder configurations, please contact us at 386-446-0500.

ITM Profile

Visit Us: Linked In Youtube Manta Facebook Twitter Google+

* ITM * Tool Grinder * Tool Grinding * Tool Grinder * Tool Grinding * Tool Grinder * Tool Grinding * Tool Grinder * Tool Grinding * Tool Grinder * Tool Grinding *