Form Grinder Machine Specifications

FORM GRINDER (FPG)

MACHINE SPECIFICATIONS

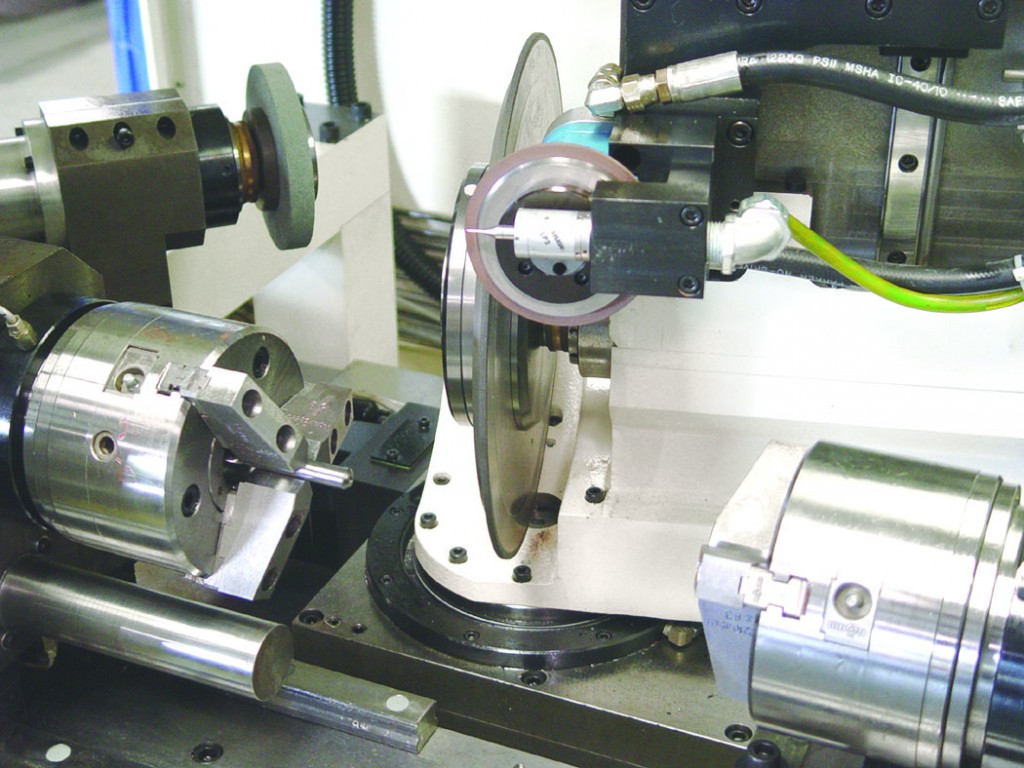

Form Grinder Inside

>> WORKPIECE DATA

- Min. Diameter 2.5 mm (.1”)

- Max. Diameter 50 mm (2”) optional 180mm (7”)

- Max. OAL 300mm (12”)

- Other dimensions upon request!

>> GRINDING WHEELS

- Diameter 350mm (14”)

- Diamond, CBN

- Up to 150 m/s (30,000 sfm)

>> MACHINE DIMENSIONS

- Height: 2440mm (96”)

- Width: 2530mm (100”)

- Depth: 2600mm (102”)

- Weight: 5,000 kg (11,000 lbs)

ITM Tool Grinding Machines are Designed for 24 Hour Production…

7 Days a Week.

In order to produce finished cutting tools you must begin with a prepared blank. The challenge is to produce a machine for Carbide and HSS blank preparation that is both flexible and very productive.

ITM’s Form Grinder (FPG) is designed to form both ends of a part complete in one setup. Two rigid chucks are mounted opposite each other onto high precision rails. For maximum support during grinding, the parts are clamped as deep as possible into the precision chucks that maintain 0.01mm concentricity. For utmost flexibility the chuck jaws have a clamping range of 8.5mm. If chucks are installed that use a set of precision ground jaws per diameter, the concentricity can be maintained within 0.002mm. The machine can be equipped with an automatic cassette loader to allow for hours of unattended operation.

For more information regarding ITM Form Grinder configurations, please contact us at 386-446-0500.