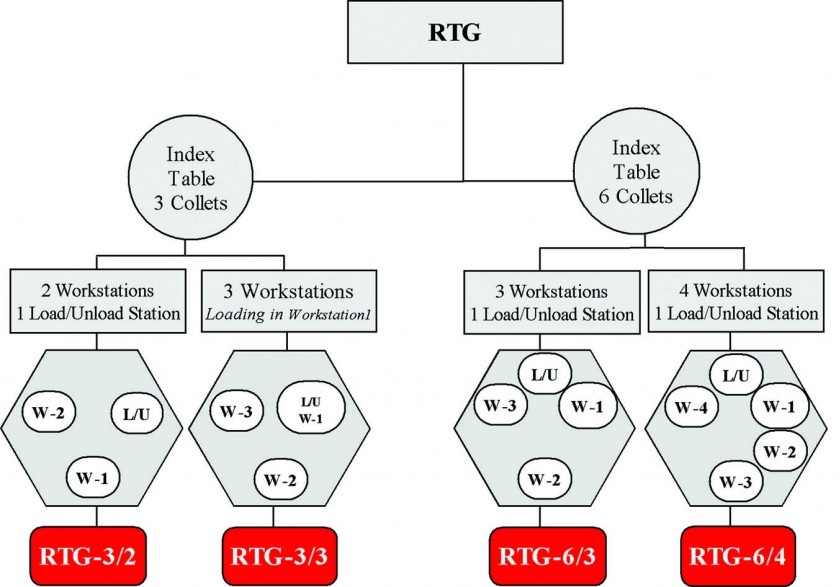

RTG – CONFIGURATIONS

ROTARY TRANSFER GRINDER (RTG)

MACHINE CONFIGURATIONS

RTG – APPLICATIONS / GRINDING OPERATIONS

RTG – MACHINE FEATURES

RTG – MACHINE SPECIFICATIONS

RTG – ROTARY SERIES

The Rotary Transfer Grinder is the latest model of ITM’s Multi-station Grinders.

The RTG resembles a compact grinding cell consisting of up to 5 precision grinding stations connected by a high speed rotary transfer mechanism! The RTG stations can be configured to grind Flutes, OD-Relief, Points, Face, Counterbores, Chamfer, Groves, Endteeth, Endface ID, flip parts, and production of parts that require multiple surfaces to be ground. With up to 21 CNC controlled axes, setup time is fast (less than 15 minutes), making the machine economical for both large or small production runs.

To begin the cycle, a part is presented to the loading station. ITM can provide an automated load/unload station with an integrated Fanuc robot turnkey system. The rotary table can carry up to six collets which indexes for accurate and fast part exchange from station to station . The loaded part is now at the first workstation. Next, all of the workstations perform their programmed grinding application and another part is simultaneously loaded/unloaded. The workstations can be designed and arranged in a variety of combinations depending on your application and all stations work simultaneously. Which makes the total production time equal to the longest single operation plus transfer time. Making this the perfect production machine for your tools and parts.

For further information regarding ITM’s Rotary Transfer Grinders, please contact us at 386-446-0500.

ITM Tool Grinding Machines are Designed for 24 Hour Production…

7 Days a Week.