THG – SAMPLE APPLICATIONS

THREAD GRINDER (THG)

SAMPLE APPLICATIONS / THREAD GRINDING OPERATIONS

THG – MACHINE SPECIFICATIONS

THG – THREAD SERIES

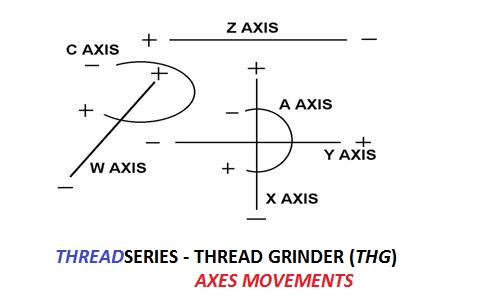

THREAD GRINDER

Thread grinding is done using specially dressed grinding wheels matching the shape of the threads. This CNC grinding process is usually used to produce accurate threads or threads in hard materials.

This new concept in grinding machines was developed for the economic grinding of threads for taps, thread rolls, or other parts requiring a thread with or without relief or precision ring grooves (as used on crush rolls for example).

ITM Thread Grinders use specially dressed grinding wheels that match the shape of the threads. The process is usually used to produce accurate threads or threads in hard materials. In general, we recommend single ribbed wheels, however multiple ribbed wheels are also available (depending on the application). To complete the thread multiple passes are common.

SAMPLE APPLICATIONS / THREAD GRINDING OPERATIONS

-

Taps: Thread and Chamfer in the same clamping

-

Thread Gages, Form Taps

-

Bone Screws

-

Thread Rolls with up to 400 starts

-

General Thread Grinding with or without relief

-

Multi-rib or Single-rib Grinding

For further information regarding ITM’s Thread Grinders, please contact us at 386-446-0500.

ITM Tool Grinding Machines are Designed for 24 Hour Production…

7 Days a Week

ITM Profile

* ITM * Tool Grinder * Tool Grinding * Tool Grinder * Tool Grinding * Tool Grinder * Tool Grinding * Tool Grinder * Tool Grinding * Tool Grinder * Tool Grinding *